Electric heaters are shell and tube heat exchangers that use electric power which is converted to heat. They can be used when there is not any other heating source available for heating lubrication oil or water.

Environmentally friendly devices

Ideal for Heating Oils (Fuel, Lub.) or Water

Easily replaceable Ceramic Heating elements

Fuel Savings for Aux. Boilers

Emission Reduction from Aux. Boilers

Zero Emission in Port (Power Supply by AMP)

Low Operation Costs

Wide heat duty range.

Operational Flexibility & Reliability

FARAD’s Electric Heaters Series

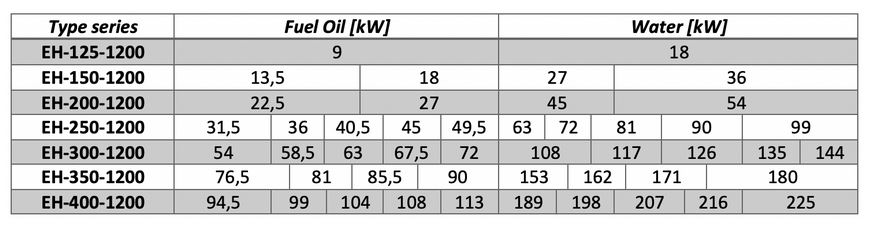

Farad’s Electric Heaters are designed to work with high viscosity crude oils as well as lubrication oils and water when there is no other heating medium available. The EH series heat exchangers are primarily used as initial or extra heating of oil or water in the shipping industry. Their flexible design and wide heat range (from 9 kW to 225kW) makes them well suited for any application where backup or booster heating is required or where electric power is the cheapest or the only available power source.

Long life removable ceramic core heating elements are designed for optimum trouble-free service and ease of maintenance. A failed electric element can be replaced without the need to isolate and drain the heater.

Low surface load (W/cm2) reduces the risk of damaging highly viscous fluids while improving flow ability of fuel oils. As a result, heating elements are protected from over-heating and failing prematurely.

Heavy fuel Oil: 1.5 W/cm2

Lubrication Oil: 1.5 W/cm2

Fresh Water: 3.0 W/cm2

Optional, 3 to 5-steps startup configuration with all controls prewired.

Pump Interlock function as a standard.

Selector switch for operation based on viscosity signal (4-20mA) prepared by shipyard.

All Farad Electric Heaters from EH range are fitted with an adjustable temperature controller (with PT-100 temperature sensor) and an overheating thermostat.

Warranty 24 months after delivery.

Each unit built by FARAD undergoes hydraulic and electric testing.

Materials

Materials are sourced from reputable EU manufacturers and material thickness is higher than that required by the relevant design code. Stainless and carbon steel are used. Heating elements are made of high quality ceramic material.

Design parameters

Industry leading heat exchanger software is used to find the required heat exchanger dimensions based on customer requirements. Additional standard design parameters are listed below:

Design pressure: 16 barg

Test pressure: 24 barg

Design Temperature: 160 oC

Flanges PN16 DIN 86030/EN1092-1

Standard feature/accessories of FARAD’s electric heaters

Safety valve

Drain valve (AISI-316)

Air vent valve (AISI-316)

Thermometers (L-form),2pcs

PT-100 sensor

Safety thermostat (Marine type)

Approvals

All electric heaters are compliant with European Legislation covering CE markings/PED approval and can be certified by various classification societies (ABS, BV, DNV-GL, LR) upon request.

Delivery

Delivery within 2-4 weeks from order receipt. Some models may be available for immediate delivery (in- stock).

![]()

14 Alon Street, Piraeus - GR18540 Greece

Phone: +30 2104227410

Fax : +30 2104227303

Email:

WEb : www.farad.gr